Nissan to unveil plans for Britain's first electric car battery gigafactory

The TelegraphNissan's Sunderland plant has about 6,000 staff and supports almost 30,000 jobs in its supply chain. Professor David Bailey, an automotive industry expert at Birmingham University, said: “This is a huge boost for the UK automotive industry, guaranteeing Nissan’s presence in the UK and its supply chain for at least the medium term.” Richard Perberdy, head of automotive at KPMG, said: "It is not just about the Nissan's batteries and electric vehicles. Former Jaguar Land Rover boss Sir Ralf Speth was one of the first to signal just how important they are, warning: “If batteries go out of the UK, then automotive production will go out of the UK.” Carlos Tavares, head of Stellantis, has also highlighted the need for batteries - which account for about 40pc of the total cost of an electric car - to be manufactured near the plants where they are installed into vehicles. Assuming that once the pandemic eases UK car production returns to long-term average rates of about 1.5m vehicles a year, and if those cars are to be battery powered, Britain’s car industry will need about 100 gigawatt hours of annual battery production. How far Britain lags in the electric car race was underlined on Monday when China’s Envision outlined a €2bn plan to build a battery plant in northern France to supply Renault.

History of this topic

Europe’s Big Battery Ambitions Are Failing, and China Is Benefiting

Live Mint

The EV Transition Is Leaving the UK Auto Industry Behind

Live Mint

European carmakers raise £4bn for gigafactories in race to cut reliance on China

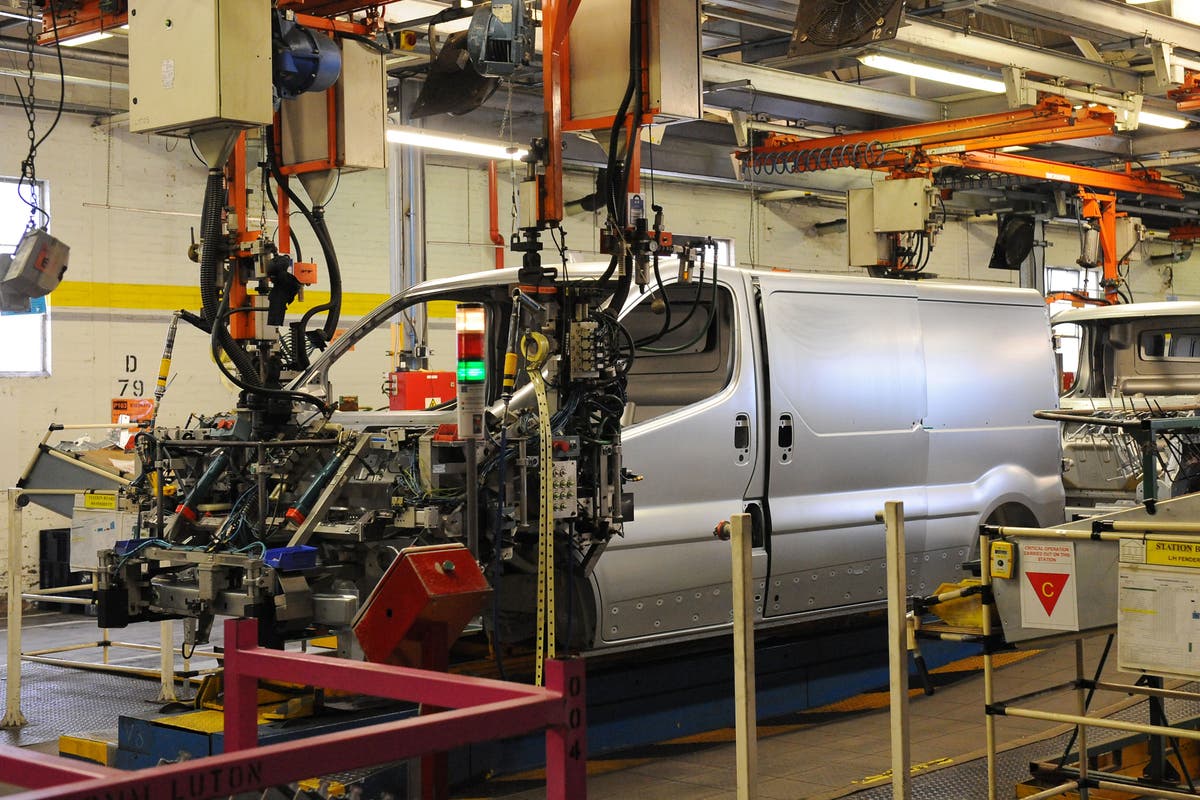

The TelegraphNissan will invest $1.4 billion to make EV versions of its best-selling cars at its UK factory

Associated Press

Nissan to produce two new electric car models in Sunderland

The Independent

Nissan to build electric versions of Qashqai and Juke in UK plant

Hindustan Times

Nissan unveils £2bn investment plan to build two new electric cars in Sunderland

The Telegraph

Spark EV battery production to prevent decline of UK car industry, MPs warn

The Independent

Tata Group to Invest Over £4 Billion in UK Electric Battery Factory, Creating Thousands of Jobs

News 18

India’s Tata set to bring 4,000 jobs to the UK with £4 billion battery plant

The Independent

UK to add 9,000 jobs as Jaguar Land Rover builds electric battery ‘gigafactory’

The Independent

Jaguar Land Rover will build huge £4bn electric car battery plant in Somerset in a major boost for Britain's motor industry

Daily Mail

Jaguar Land Rover owner set to pick UK for EV battery plant

Daily Mail

‘800,000 car industry jobs at risk’ unless UK renegotiates Brexit deal

The Telegraph

Nissan in talks to boost UK plant as Renault haggling continues

Live Mint

Nissan Sunderland has produced its quarter-of-a-millionth electric car

Daily Mail

Electric car ranges triple to close gap on petrol engines

The Telegraph

Nasa working on electric car battery that charges in 15 mins

The Independent

Aston Martin, Britishvolt to develop battery technology for high performance cars

The Hindu

Renault, Nissan to Invest $26 Billion in Future Electric Vehicles; Unveils EV-Based Platform

News 18)

Nissan’s electric microcar will come with 20 kWh battery and driver assists, to debut in 2022

Firstpost

Nissan unveils plans for £1billion 'gigafactory' in Sunderland

Daily Mail)

Volkswagen to Build At Least 6 Gigafactories in Europe by 2030, to Overtake Tesla in the Region

News 18

Geely is spending $4.6 billion on battery plant as its electric car ambitions grow

CNN

Britishvolt to build UK's first electric car battery 'gigafactory' in Blyth

The TelegraphDiscover Related

)

)

)